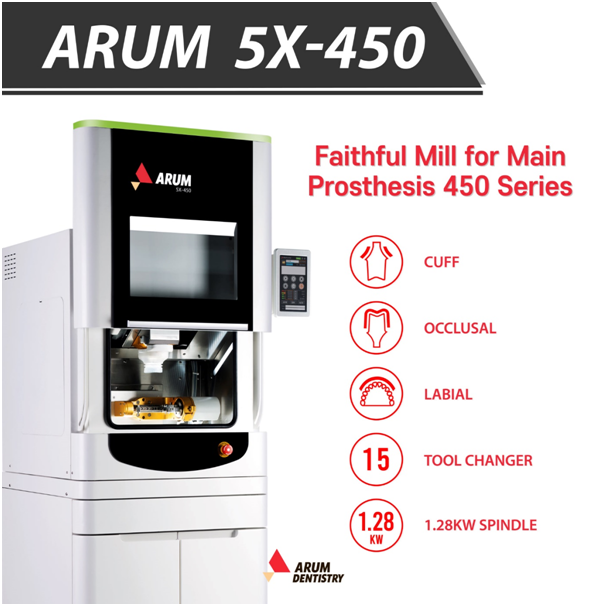

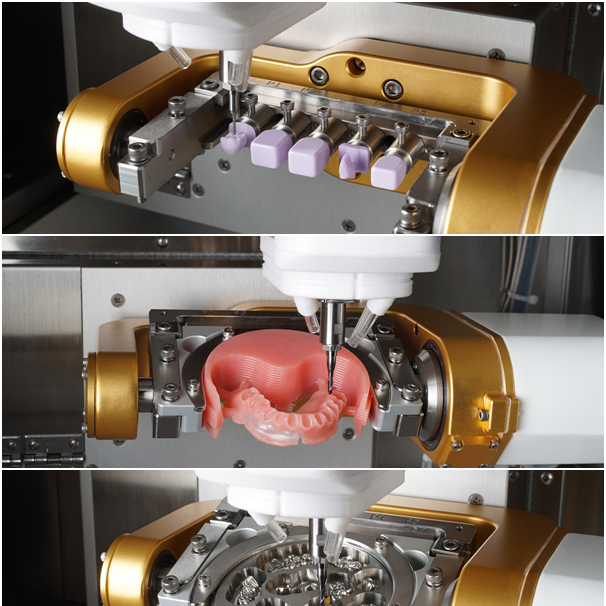

ARUM 5X-450 for machining various prostheses

With use of open C type cartridge, you can precisely machine Labial Side (Buccal Side) and Under-Cut zone that requires additional machining.

With the amazing power of the best-in-class spindle AC 1.28kw, you can machine various shapes and materials such as Denture, Zirconia, CAD Block, and Titanium milled Bar. Etc

PROGRAMAT P310 G2 FURNACE

Modern,Intuitive,Smart.With the objective to meet the requirements of your dental laboratory.Proven technologies.such as the infrared technology,combined with new features-that is what makes the new Programat ceramic furnace your reliable specialist.

High process reliability due to infrared technology(IRT)[I]:The integrated thermographic canera is sensitive to infrared radiation and measures the temperature directly at the surface of the objects being fired.

the furnace head and the heater are controlled with the infrared camera to ensure that the predefined pre-drying temperature is consistently maintained on the objects in the furnace.

ZUBLER VARIO 230

There is a considerable difference between the available and usable space inside a ceramic oven. The available space is generally considered to be the diameter of the fi ring tray plus the working height. The usable space, conversely, includes the thermal conditions of a fi ring chamber.

The heating coils used in ceramic ovens radiate at temperatures far above 1000 ° C during the sintering phase. Consequently, temperatures in direct proximity to the heating coil are 'useless' for consistent results when processing dental ceramics.

Zubler is the only ceramic oven manufacturer in the world to address this problem and develop a fi ring chamber with a larger inner diameter.

The VARIO 230 series ceramic oven's 120mm inside diameter ensures temperature homogeneity across the entire 80mm-diameter fi ring tray, irrespective of the position or number of objects.

HIGH PERFORMANCE 3D PRINTERS

3D Printing is revolutionizing the digital dentistry industry. Procedures that once took weeks now take just hours with chair-side production of dental models and surgical guides, putting local dentists in full control of patient-specific products. The ability to produce applications from digital files including night guards, temporary crowns, and dentures, means that fewer appointments are needed, turnaround times are quicker, and cost is vastly lowered, resulting in an overall improvement in patient care.

As a dental practitioner or a specialist in a dental laboratory, you know that there's a world of difference between dental models for patient education and dental parts for patient use.

If your goal is to print reasonably accurate models of a patient's mouth taken from an oral 3D scan or impression in order to, for example, explain a procedure to a patient, then there's no need for a specialized dental printer. In fact, you have a much wider range of printers to choose from for model making than you do for printing parts that will come in contact with a patient.

THE NEW AND IMPROVED T-SERIES LAB SCANNERS

The Medit T710 desktop scanner is equipped with a fast scan engine and highly efficient software algorithm which work in tandem to produce a fulFkarch scan in just 8 seconds. The advanced, high-speed positioning system of the new T-Series is designed for optimal performance for your laboratory, speeding up your workflow and increasing productivity.

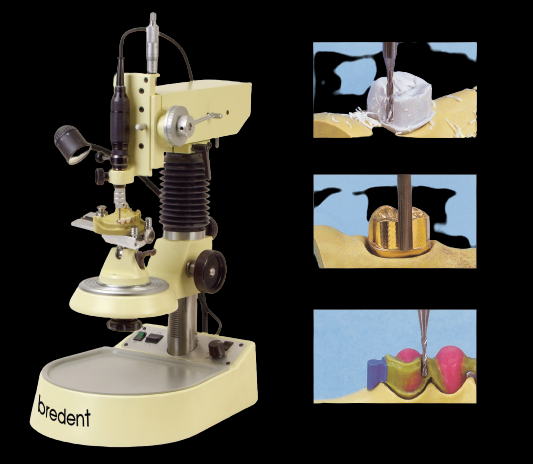

The milling machine BF 2 is intended for use in a dental laboratory. It has a 3-dimensional milling arm, which can be used as a parallelometer (scraper) or for milling, drilling or grinding.

The standard materials present in a dental laboratory, e.g. wax, plastic and metal, can be processed using this milling machine. When using rotating tools, the limit values of the tool manufacturer must be observed.

PROGRAMAT EP3010 G2 FURNACE

The Programat EP 3010 is characterized by its exceptional user-friendliness. The desired program can be quickly selected on the high-resolution, colour touch screen or on the proven membrane-sealed keypad. The clearly structured menu contains modern icons, which direct the user to the desired program or setting with only one click.

The electronic press drive with force sensor records and controls the pressure of the press plunger very precisely and therefore ensures top-quality press results. A compressed air connection is not required.

The Programat EP 3010 features the Crack Detection System (CDS). This system identifies cracks in the investment ring at an early stage and reduces the pressure, if necessary. As a result, the press process ends in time to protect the restorations

temperature checking system calibrates the temperature in the furnace fully automatically and in two different temperature ranges. This ensures high-precision press and firing procedures and reproducible press and firing results with various types of materials (low- and high-fusing ceramics).

Ivoclar BPS Injection moulding

The predosed SR Ivocap High Impact denture base material demonstrates a consistent quality because it is mixed to a clean homogeneous consistency in the Cap Vibrator.

SR Ivocap High Impact shows a marked improvement in quality over the predecessor material, due to a 25% increase in the impact strength. The material complies with EN ISO 20795-1.

Lampert PUK D5 Micro-pulse welder